1991 -The company was established, and in the early years,

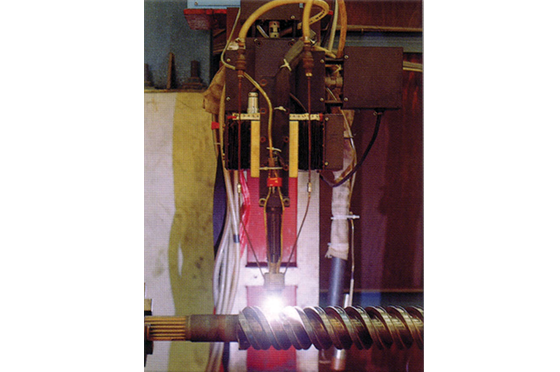

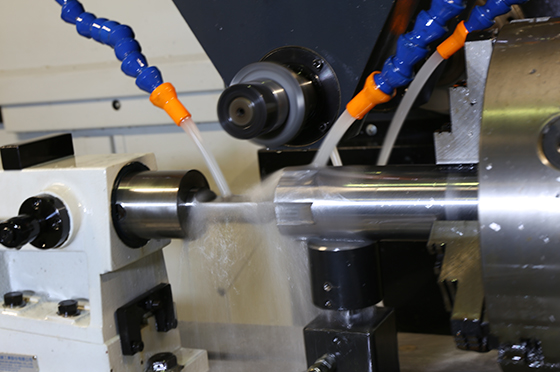

it provided services on a contract basis for customers doing PTA

(Plasma Transferred Arc). This processing work consisted of taking

alloy in powder form and plasma coating onto the screw threads

in order to increase the durability of the screws.

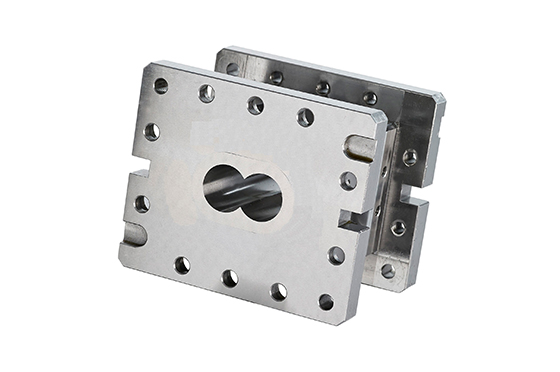

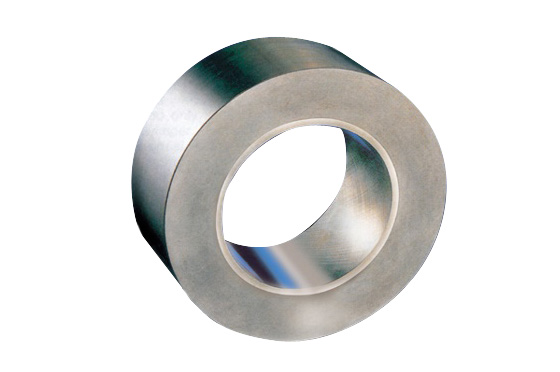

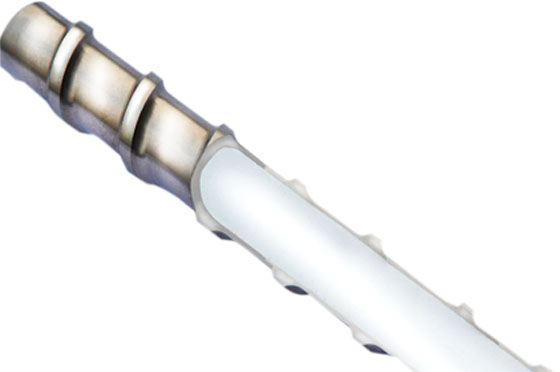

1994 -Started the development of Bimetallic Barrels

(Bimetallic Cylinders)

1995 -Successfully manufactured Taiwan’s first Bimetallic Barrel (Bimetallic Cylinder)

1996 - Achieved a major breakthrough in manufacturing

technology for the product and started the production of

Bimetallic Barrels (Bimetallic Cylinders).

1998 - Introduced a series of Bimetallic Barrel products, including the TCB-12 Bimetallic Barrel, TCB-20 Bimetallic Barrel, TCB-60 Bimetallic Barrel, TCB-90 Bimetallic Barrel and so on.

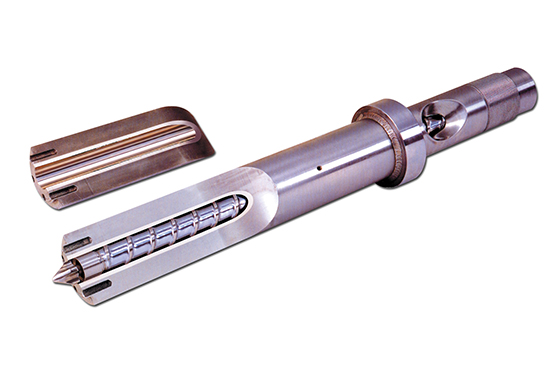

2001 - Succeeded in manufacturing the very first screw of thru hardened steel in Taiwan.

2003 - Advanced production technology of Bimetallic Barrels allowed us to dramatically improve the quality of metal alloy casted products.

2005 - The first screw grinding machine for thru hardened steel was put into operation.

2006 - Imported a vacuum furnace that enables us to complete the heat-treating process for the screws in our own factory.

2007 - Imported a machine for computerized machining of the exterior of a barrel.

2009 - Imported a larger screw grinding machine for thru hardened steel, with a maximum length capacity of 2000 mm.

2010 - In an effort to meet market demand, we imported a vertical vacuum furnace with a maximum length capacity of 2300 mm to enable complete in-house pre-hardening of steel processing.

2011 - Started research and development on fully covered alloy screws.

2014 - Manufactured and conducted prototype testing of the first fully covered alloy screw.

2015 - Established Element Metal Co., Ltd. to directly respond to inquiries about export.

2016- Our continuing research and development in this field

is designed to provide our customers with the products with

the highest quality that can last as long as possible.